The Acid Regeneration Plant Reactor

Reactor Contruction

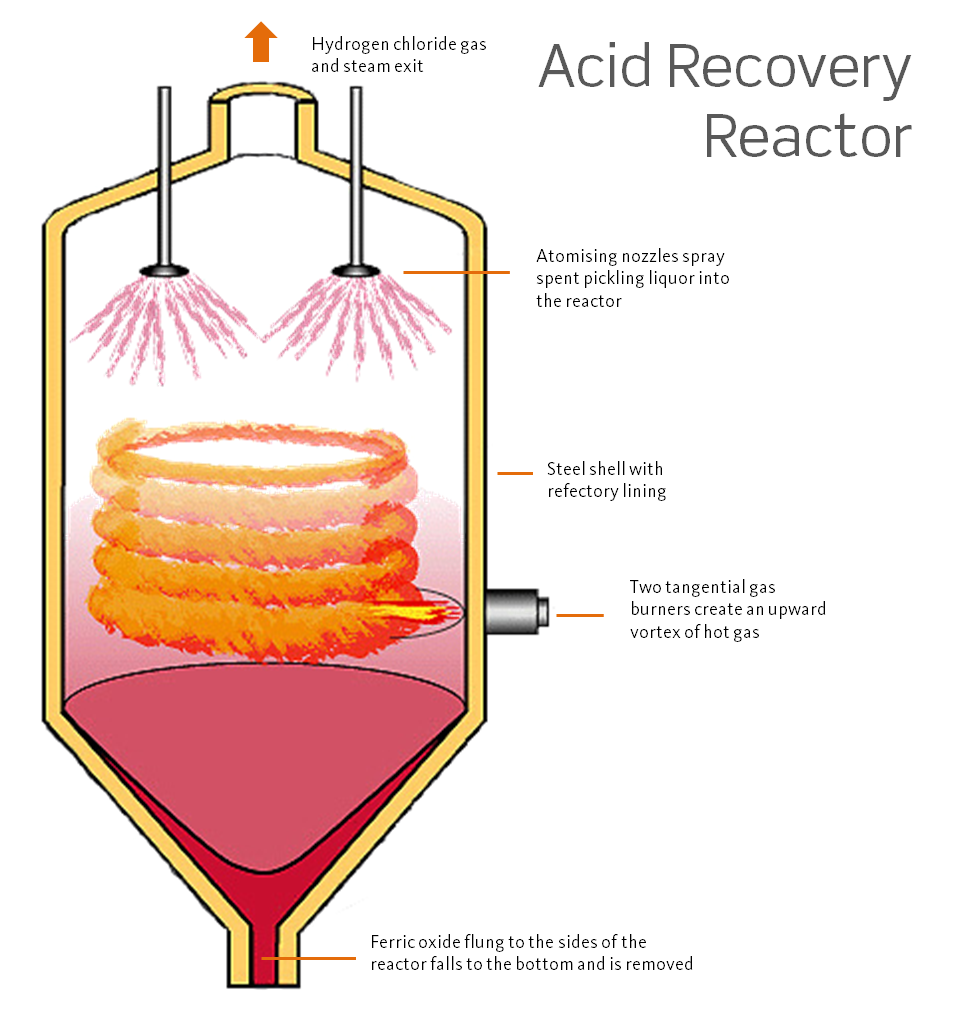

A reactor is a vessel where a controlled chemical reaction can take place. The acid regeneration plant reactor is a vertical cylindrical mild steel shell with a coned bottom and shallow dished roof. The reactor vessel is 14 metres high and 3 metres wide. The sides and bottom are refractory lined due to the high temperatures reached inside the reactor. Burners are mounted tangentially to create a vortex.

Chemical Reaction Inside the Reactor

The nozzles are used to break up the spent pickle liquor into very small droplets. When these droplets are heated up, a chemical reaction takes place.

The water and ferrous chloride will react with oxygen to form hydrogen chloride gas and ferric oxide dust. The oxygen for the reaction is provided from the combustion gases. The air/fuel mix that is supplied to the burners has a 20% excess of air.

Ferric Oxide and Hydrogen Chloride Gas Separation

To ensure that proper separation occurs between the hydrogen chloride gas and the ferric oxide, an upward vortex gas flow pattern is produced by the tangentially placed burners. The vortex gas flow pattern will centrifugally fling the ferric oxide dust to the sides of the reactor.

Once at the sides of the reactor the ferric oxide will fall down the sloping sides of the conical bottom and out of the reactor.

The hydrogen chloride gas, steam and any entrained ferric oxide dust will pass out from the top of the reactor.

Reactor Temperature

The combustion gases are injected into the reactor by the burners at 1300°C to

1400°C.

The temperature at the top of the reactor is 350°C to 400°C, at the middle of the reactor the temperature is 600°C to 700°C and at the bottom of the reactor the temperature is 420°C.