Keeping Air Clean

While New Zealand Steel monitors closely all its operations to minimise any effects on the environment, by far the biggest percentage of the company's capital investment in environmental control is in the improvement of the quality of its emissions into the atmosphere.

Improving air quality starts with making sure the emissions are as clean as possible before they leave the process. For example, waste gases produced by the steelmaking, rolling and coating facilities at the Glenbrook Mill must be cleaned before they can be discharged into the atmosphere via tall stacks or vents. The scale of the cleaning operation is enormous with more than 3 million cubic metres of waste gas being cleaned each hour the steel mill is working at full capacity. Large extraction fans and ducting pull the dust laden gas from the processes and direct them to either a wet scrubbing system or a dry bag house.

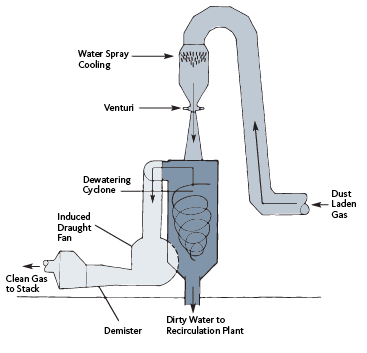

The wet scrubbers wash dust from the hot process waste gases coming from iron and steelmaking processes. Wet scrubbers come in various shapes, sizes and configurations depending on the volume and composition of the waste gas. The diagram (below) shows part of a wet scrubbing system for the multi-hearth furnaces. The bag house filter operates just like a vacuum cleaner by filtering dust out of the gas using cloth bags. Compressed air is periodically blasted into the dust-coated bags to knock the dust down into the collecting hoppers. The amount of dust collected in air pollution control equipment and thereby prevented from entering the atmosphere is estimated to be between five and ten tonnes per hour. The largest baghouse can clean a million cubic metres of dust laden air an hour. There are three large baghouses in the iron and slabmaking plants and a number of small baghouses located throughout the Glenbrook site.

A major initiative to offset emissions is a cogeneration plant, recycling surplus gas from the iron-making kilns to produce up to 60% of our electricity needs.

New Zealand Steel has an air-quality monitoring programme at the boundaries of its site and in the neighbouring community. Weekly samples are collected for evaluation against strict ambient guidelines.

Sound Quality

Integrated acoustic design, the layout of the plant, silenced equipment and thermal insulation all contribute to noise levels below local Council standards. Very high noise processes are carried out in special acoustic structures.