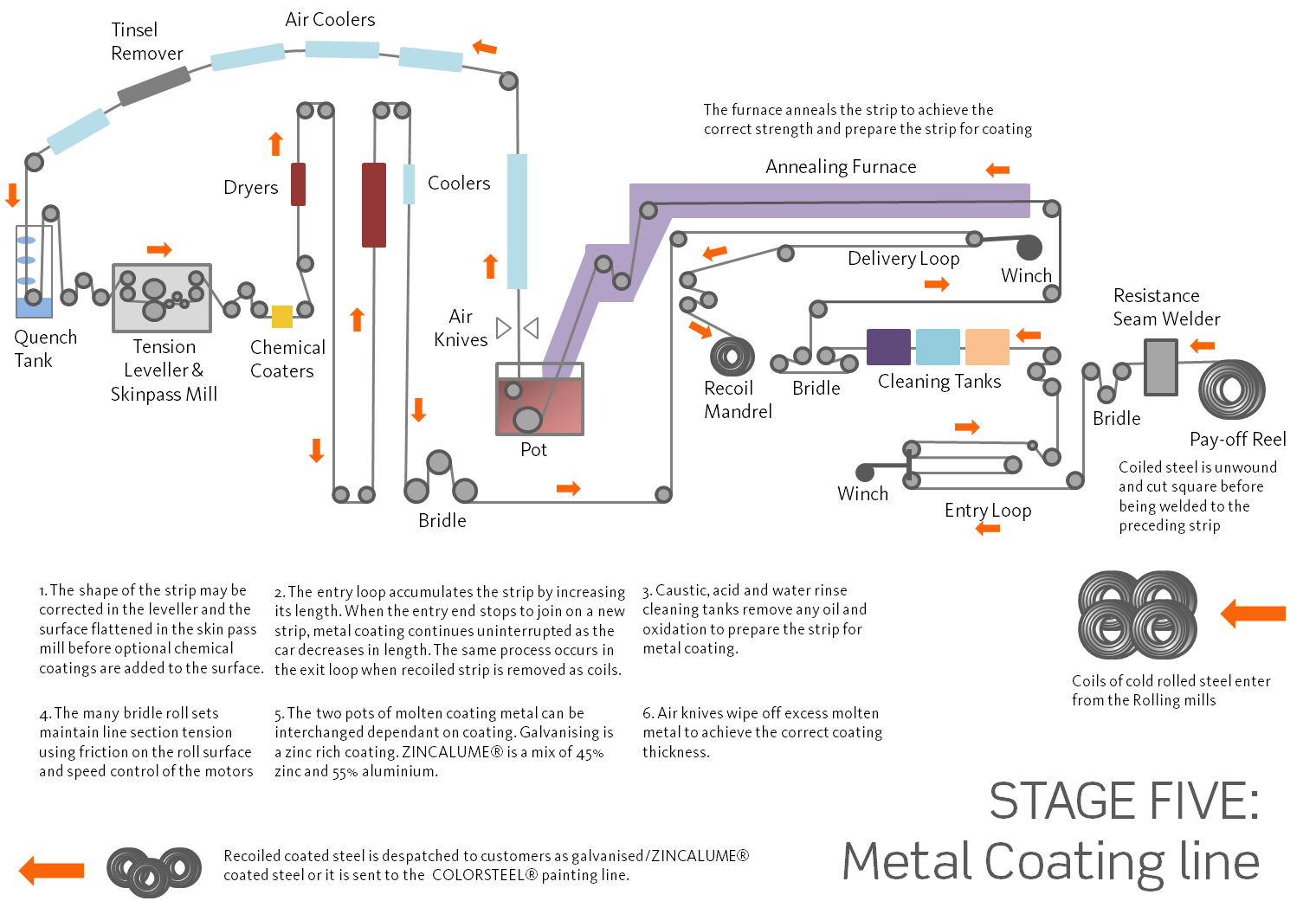

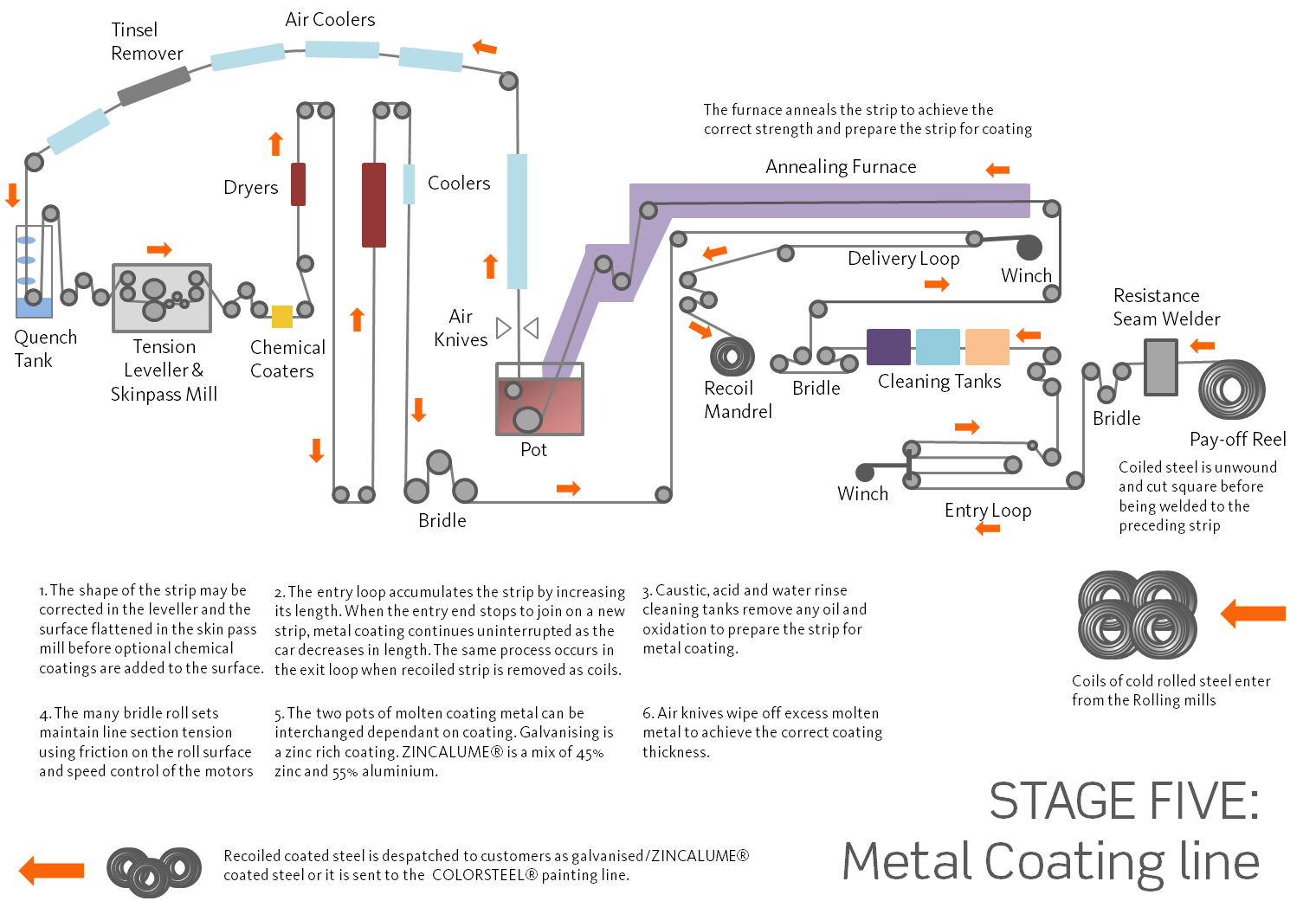

New Zealand Steel's metal coating line produces both ZINCALUME® and galvanised steel. Cold rolled strip is delivered from the cold rolling mills to the metal coating line. The strip is cleaned to remove grease, oil and iron oxide before traveling through the annealing furnace (with a hydrogen and nitrogen atmosphere) to anneal or stress relieve to the specified strength. The strip travels into the molten metal through the "snout", where it emerges below the surface of the metal. The strip travels vertically from the pot, passing through air knives which control the coating thickness. The coating is cooled and moved through the skin pass to flatten the metallic coating on the strip. To protect the surface from oxidation, a passivation solution is applied. The strip is then branded and wound, ready for packing.

Check our FAQs, call our support line or you can contact us through our online form.

0800 100 523